By Lindy Faulkner, Assistant Manager

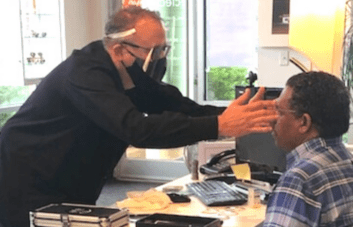

Shopping for new glasses can be fun for some and daunting for others. At Eclectic Eye, we pride ourselves on making shopping for eyewear an enjoyable and stress free experience. After exploring the shelves, debating color options and possibly snapping a few selfies, it’s always exciting to find the ONE (or two, or three).

After discussing lenses with your Eyewear Architect, you’re out the door with the promise of receiving the ideal frame for the canvas that is your face. While we adore the frame selection process, the real Eclectic Eye magic starts after your selections are made. Here is an inside look at what happens next.

Order Details:

The success of our lab hinges on the notes and details made by each Eyewear Architect. Your eyewear order is a story of your information, all concisely laid out to ensure you get exactly what you need. Our team goes above and beyond industry standards to provide a patient with the best look and visual acuity possible by focusing on every single detail.

Tray Construction:

These details are placed into a designated tray, which is labeled to ensure your prescription and handcrafted frame are built accurately. Once your prescription lenses are ordered, an Eyewear Architect double-checks that all information is correct, and your frame travels to the lab.

Lab Integration:

Now that the order has made it back to the lab, it’s integrated into the pending orders section. The lab is organized by vendor, and each order is placed in its proper “waiting room.” When the order arrives, we record all pertinent information in the invoice, so that we have access to the specifics of the order for years to come.

First Inspection:

Lenses arrive to our lab in blank form. At first inspection, we immediately check for scratches and/or defects and confirm that the prescription and parameters ordered are exact.

Edging and Mounting:

This is the stage where things start to come together. Once the frame is traced and the lenses are prepped for cutting, we use the best technology available to cut the lenses to shape. A highly trained optician monitors this meticulous process, since it varies based on the specific prescription, frame size/style and mounting style.

Once the cutting of the lens is complete, it must undergo finishing. For some frames, edges must be polished, drill details added or even sizing completed by hand. When you handle handmade eyewear in a lab setting, there are zero corners to cut. No two shapes are exactly the same, so universal patterns are often impossible.

We want to confirm each lens meshes seamlessly with the design of the frame and all edges are clean. Once this is complete, the lenses are mounted into the frame. Different materials require varying levels of pressure, heat, tools and manipulation to make this happen. For example a Cutberth & Chin buffalo horn frame requires a different process as opposed to a semi-rimless titanium Lindberg.

Final Inspection:

Final Inspection:

Your completed glasses now require a secondary, more precise inspection. Most importantly, we use a lensometer to verify the prescription. All parameters of the lens must line up with the original order and fit perfectly into the frame. A skilled eye double checks for scratches and defects, and then the inspector gives the stamp of approval.

Packaging:

Now it’s time for your fabulous eyewear to “get pretty!” We wrap your perfect accessory in the highest quality case and pair it with an Eclectic Eye cleaning kit and cleaning guide. While we strive for the best presentation, an important part is slipping them on for the first time and adjusting them to fit you perfectly. We want you to look fantastic AND see well!

Now you can take your eyewear home to wow your family, friends and coworkers with your new look.

We hope you’ve enjoyed the inside scoop on the road trip your specs must take to arrive back in your hands; flawless and ready to be your ultimate accessory. We love helping you select the perfect frame and want you to enjoy the fruits of our hard work. This process is the definition of a labor of love!